Part II: Morris Chang's 2021 Speech on the History and Future of Semiconductors

"Samsung Electronics is a strong competitor of TSMC...because the advantages of South Korea in wafer manufacturing and Taiwan are similar."

Happy holidays everyone! Thank you for subscribing to the Substack edition of Interconnected, among more than a thousand other readers, since our launch on Substack less than four months ago. (Network effect is a beautiful thing!)

Today’s post is Part II of the translation of an hour-long speech Morris Chang delivered on the history and future of semiconductors and TSMC in April 2021 in Taiwan. (The original video of the speech, delivered in Chinese, can be found here.) Due to the length of the speech, we are publishing it in two parts. Part I of the speech can be found HERE. This translation also includes screenshots of the slides (in traditional Chinese) Chang used during his speech.

In this Part II, you will read Chang’s unfiltered analysis and opinion of the relative strengths and weaknesses among Taiwan, Mainland China, the US, and South Korea when it comes to semiconductor manufacturing. (Noticeably, he left out Japan.) I hope you enjoy reading and pondering about this important speech from one of the remaining “founding fathers” of the semiconductor technology.

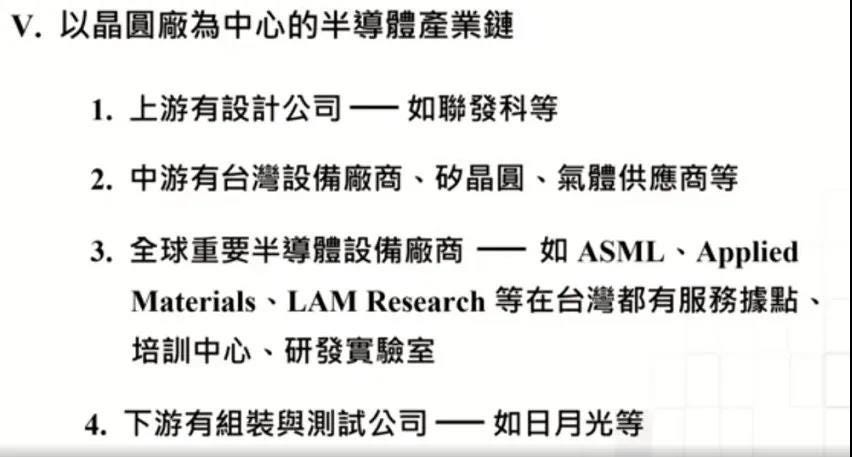

Fab-Centered Semiconductor Industry Chain

Okay next slide. TSMC is definitely not the only company in the industry. There are design companies like MediaTek —— perhaps the largest among all but there are many more. Midstream in the industry chain are Taiwanese equipment manufacturers: silicon wafers, gas suppliers, raw materials and so on. There are also important global semiconductor equipment vendors, such as ASML, Applied Materials, LAM Research, etc. all of which have service bases, training centers, and R&D laboratories in Taiwan. They are brought here by TSMC. Of course, I’m talking about TSMC today, but there are other wafer manufacturing companies in Taiwan besides it. Downstream are assembly and testing companies, so there is a fairly complete industry supply chain in Taiwan.

Origin of Professional Wafer Manufacturing

How did the professional wafer manufacturing model come about? It was a coincidence of events, places, and people in 1985 (风云际会). The “event” was the VLSI program of ITRI (Taiwan’s Industrial Technology Research Institute), which had been in operation for ten years at that point, and frankly speaking, it was at the end of its rope. It needed a lot of funding every year, but whenever it tried to do some small business, people would say that it was competing against the people of Taiwan for profit.

At the beginning, its technology was only one generation behind the world's most advanced technology. ITRI took RCA’s technology in 1975, but RCA itself was not first-class at that time, so the technology ITRI brought back was already behind. After ten years of working on it, the gap became even bigger. They were then two or three generations behind. It also cost quite a lot to employ hundreds of people. If it did some small business, it was accused of competing against the Taiwanese people for profit.

So Mr. Li Kwoh-ting wanted to find a way out, and I took advantage of that opportunity. This was definitely not hitchhiking. The foundry model was the world's first. Although the upside was that there were no competitors, the downside was that there were no customers either. I’m not going to talk about this today.

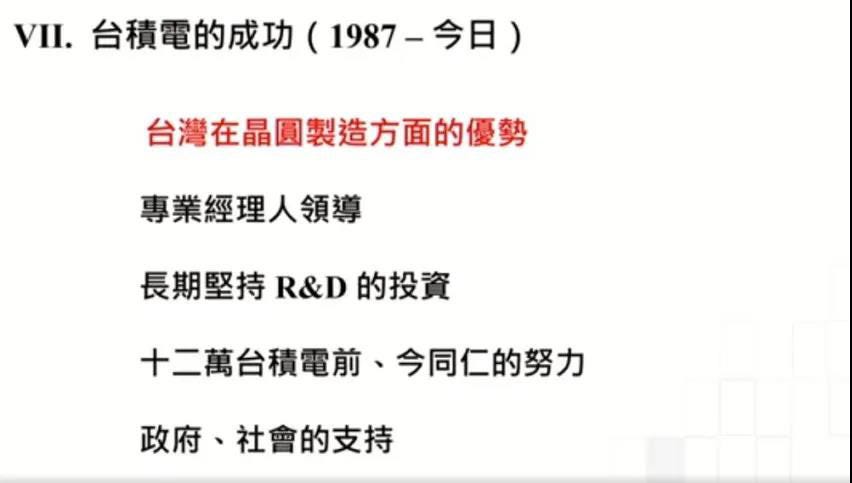

TSMC’s Success

Why did TSMC succeed? What are the factors behind it? The most important factors are what I’ve just talked about: Taiwan’s advantages in wafer manufacturing.

Of course professional managerial leadership is important too. I think TSMC is the largest company in Taiwan and led by professional managers, everyone from the chairman down. Of course, there are disadvantages as well, but I do think that to set up a world-class enterprise, deploying a professional managerial leadership is still a better model.

We have been investing in R&D for a long time as well. This is what we’ve done and important for our success.

We’ve also had 120,000 employees since our founding, including those who have left. This actually indicates a very low turnover rate, only about 3%, 4%. We currently have 50,000 employees and have only had 120,000 employees in total for the past 30 years.

Of course, the support from the government and society at large is very important to TSMC’s success as well. This is what I’m calling for today. I hope they will continue to support TSMC and increase the advantages of Taiwan.

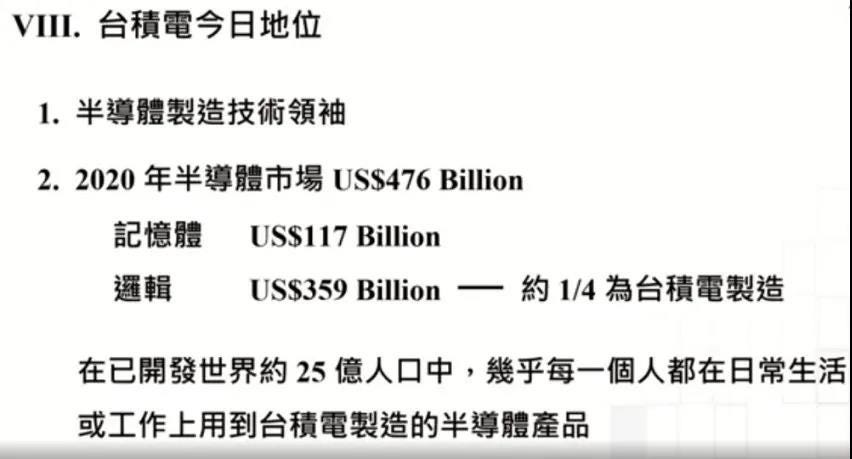

Status of TSMC Today

TSMC’s status today is the leader in semiconductor manufacturing technology.

The semiconductor market was $476 billion last year, of which memory chip was $117 billion and logic chip was $359 billion. About a quarter of that, actually just a quarter, was made by TSMC.

Almost everyone in the developed world, about 2.5 billion people, uses semiconductor products made by TSMC in their daily life or work.

For example, I actually wear a hearing aid, and I recently discovered that the integrated circuits inside the hearing aid are also made by TSMC.

Every 3 years, the hearing aid salesman comes over and tells me about the new model and asks me to buy another set. I always asked him what the benefits of the new model were, and he said a bunch of things, and then he told me that the ICs were replaced so they would function better. I actually listened to him and bought 3 or 4 of them.

Although the integrated circuit has improved over the generations, it doesn't seem to help the function of the hearing aids much, to be honest. It's kind of like the American cars, with new models every year.

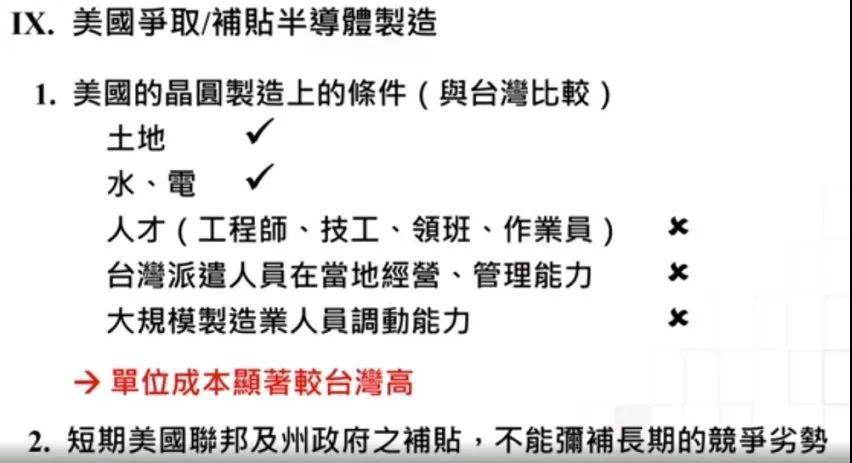

The US Subsidizing Semiconductor Manufacturing

Now let’s look at the countries we are competing against. The United States is the most powerful, with its subsidies.

Comparing the American wafer manufacturing conditions with Taiwan, land is America’s absolute advantage. So are water and electricity. However, Taiwan’s advantages that I just talked about are America’s weaknesses.

American talents are not as good as Taiwanese ones, whether it’s engineers, technicians, foremen, or operators. The personnel dispatched by Taiwan to the US, like I said, are not necessarily the best in terms of management ability. The US also lacks the ability to mobilize manufacturing personnel on a large scale.

The result is that the unit cost is significantly higher in the US than in Taiwan. It’s true that it has subsidies. The US has both the carrot and the stick, with the former being federal and state government financial subsidies. However, short-term subsidies can not make up for its long-term competitive disadvantages.

The subsidies only last for a few years, but you still have to keep going after those years.

Competition from Mainland China: After 20 Years and Tens of Billions in Subsidies

Next, competition from mainland China. After 20 years and tens of billions of dollars in subsidies, semiconductor manufacturing in China is more than 5 years behind TSMC. Logic semiconductor design is 1-2 years behind the United States and Taiwan.

Mainland is not yet a rival, especially in terms of wafer manufacturing.

Competition from South Korea: In Wafer Manufacturing, Samsung Electronics is a Strong Competitor

As for South Korea's competition in the field of wafer manufacturing, Samsung Electronics is a strong competitor of TSMC.

Why? Because the advantages of South Korea in wafer manufacturing and Taiwan are similar, from talent to the ease of transporting personnel, since Samsung’s factories are all in one place.

Its managers are also Korean, first-class in South Korea but not necessarily abroad.

Taiwan’s Next “Protective Mountain of the Nation”

Some people are now saying that we have a "protective mountain of the nation". If the definition of that is an industry that is important to the world and Taiwan has a high market share, then you need to find an industry where Taiwan has potential advantages and it’s important to the world.

Otherwise, Taiwan only has 24 million people and is a small place. I found wafer fabrication as a protective mountain of the nation, but I have not found a second one, and I have been searching for decades.

Then the next "protective mountain of the nation" needs to have an innovative product or business model, like wafer manufacturing/foundry, which was a new business model.

Then you also need many years of effort and business operations.To answer this question, my answer is: difficult!

Conclusion

Semiconductor wafer manufacturing is an important industry that impacts people's livelihood, economy, and national defense. It is also the first industry in which Taiwan has gained considerable advantages in world competitiveness. These advantages are not easy to obtain or keep. I hope that the government, society, and TSMC itself will make efforts to protect them.

This is my appeal to you today. Thank you.

Please read Part I of the speech HERE.